Microfluidics Could Be the Solution to Cooling AI Chips

Data center rack density has increased dramatically in recent years as operators pack more computing power into each server rack to meet the demands of AI and other high-performance computing applications. This surge in computing power means that each rack requires more kilowatts of energy and produces significantly more heat. Cooling infrastructure has struggled to keep up with this rapid growth. David Holmes, the global industries CTO at Dell Technologies, explains that rack densities have jumped from an average of 6 kilowatts per rack eight years ago to racks now shipping with 270 kW. He adds that by next year, racks with 480 kW will be available, and within two years, megawatt racks will become common.

To address these cooling challenges, Corintis, a Swiss company, is developing a technology called microfluidics. This method channels water or another cooling liquid directly to specific parts of a chip to prevent overheating. In a recent test conducted with Microsoft, servers running Microsoft Teams video conferencing software achieved heat removal rates three times more efficient than other existing cooling methods. Compared to traditional air cooling, microfluidics reduced chip temperatures by more than 80 percent.

How Microfluidics Could Be the Key to Boosting Chip Performance

Lowering chip temperatures through microfluidics allows chips to execute instructions faster, which increases their overall performance. Chips that operate at cooler temperatures are also more energy-efficient and experience fewer failures. Additionally, the air temperature used for cooling can be raised, improving data center energy efficiency by reducing the need for chillers and lowering liquid consumption.

Targeting the cooling liquid to the hottest parts of a chip also reduces the amount of water needed. Currently, the industry standard requires about 1.5 liters of liquid per minute per kilowatt of power. As chips approach 10 kW, this means 15 liters per minute to cool a single chip. This high water usage raises concerns among communities worried about the environmental impact of large-scale AI data centers that could house millions of GPUs. Remco van Erp, co-founder and CEO of Corintis, emphasizes the need for optimized, chip-specific liquid cooling to ensure every droplet of liquid reaches the right location.

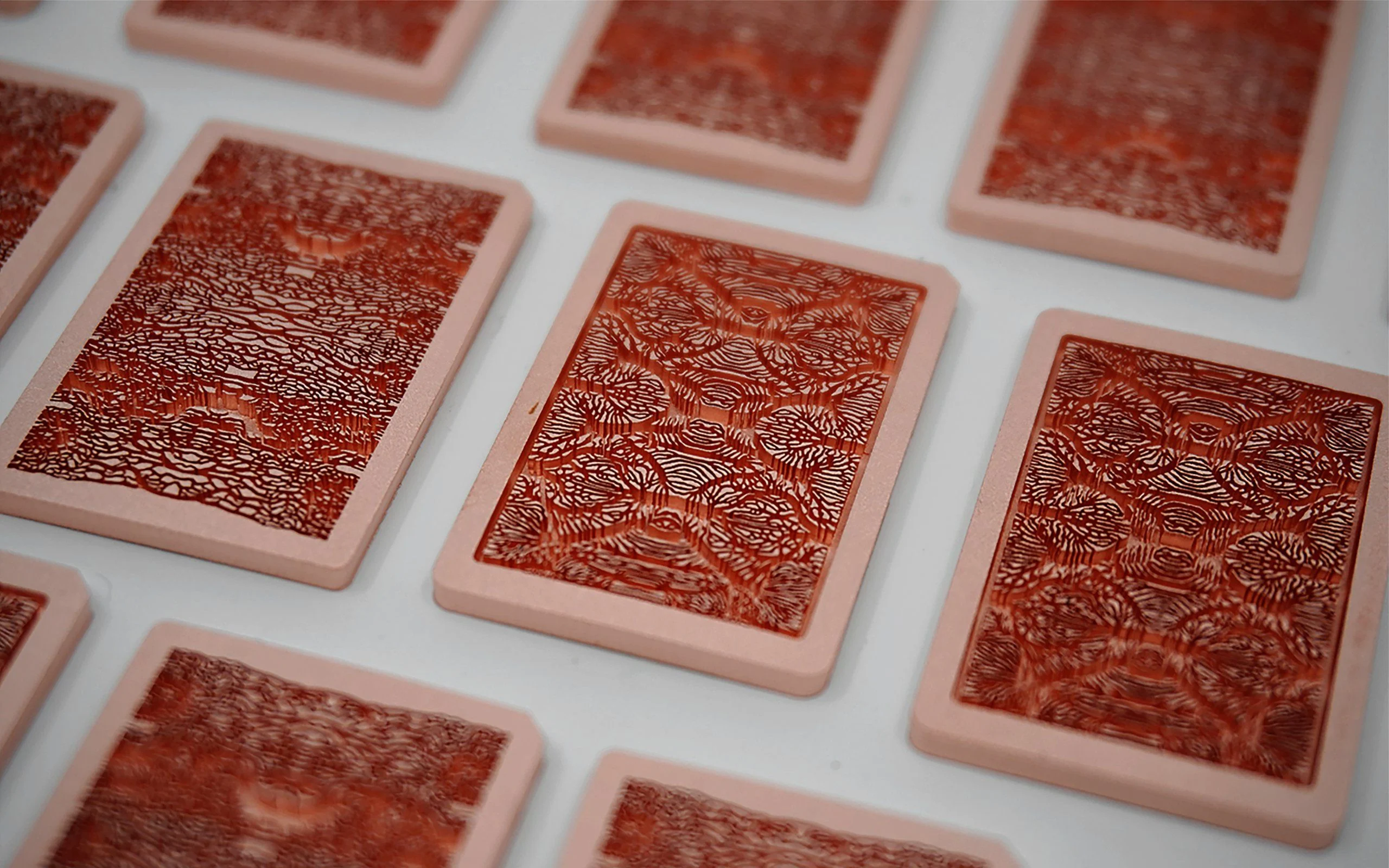

Corintis uses simulation and optimization software to design networks of microscopically small channels on cold plates. These channels resemble the arteries, veins, and capillaries in the human circulatory system. Each cold plate is custom-designed for the specific chip it cools. The company has scaled up its additive manufacturing capabilities to mass-produce copper parts with channels as narrow as a human hair, about 70 micrometers wide. Their cold plate technology is compatible with existing liquid cooling systems.

Corintis believes this approach can improve cold plate cooling efficiency by at least 25 percent. By collaborating directly with chip manufacturers to carve cooling channels into the silicon itself, the company envisions achieving tenfold improvements in cooling performance in the future.

Advancing Liquid Cooling for AI Chips with Microfluidics

Liquid cooling is not a new concept. For example, the IBM 360 mainframe was water-cooled over fifty years ago. Today, liquid cooling mainly involves two approaches: immersion cooling, where racks or entire rows of equipment are submerged in cooling fluid, and direct-to-chip cooling, where cooling fluid is channeled to a cold plate placed against a chip.

Immersion cooling is not yet widely adopted, while direct-to-chip cooling is commonly used to keep GPUs cool. However, direct-to-chip cooling only cools the chip surface. Van Erp points out that current liquid cooling methods are one-size-fits-all solutions with simplistic designs that are not tailored to individual chips, limiting heat transfer efficiency. He explains that the optimal design for each chip involves a complex network of precisely shaped micro-scale channels adapted to guide coolant to the chip’s most critical regions.

Corintis is already collaborating with chip manufacturers to improve cooling designs. These manufacturers use Corintis’ thermal emulation platform to program heat dissipation on silicon test chips with millimeter-scale resolution. They then measure the resulting temperature after applying the chosen cooling method. In this way, Corintis serves as a bridge between chip design and cooling system design, enabling chip designers to create future AI chips with superior thermal performance.

The company’s next goal is to unify chip and cooling design processes. Currently, chips and cooling systems are separate elements, and the interface between them is a major bottleneck for heat transfer. To achieve a tenfold improvement in cooling, Corintis envisions microfluidic cooling channels etched directly inside the microprocessor package rather than on cold plates around the chip.

Corintis has already produced over 10,000 copper cold plates and is expanding its manufacturing capacity to produce one million cold plates by the end of 2026. The company has also developed a prototype line in Switzerland to create cooling channels directly within chips, rather than on cold plates. This prototype work is intended for small quantities to demonstrate basic concepts before handing over to chip makers and cold plate manufacturers.

Following the successful Microsoft Teams tests, Corintis announced plans to expand by opening U.S. offices to serve American customers and an engineering office in Munich, Germany. The company also completed a $24 million Series A funding round led by BlueYard Capital and other investors. With these developments, microfluidics could be the breakthrough technology that meets the growing cooling demands of AI chips and high-performance computing.

For more stories on this topic, visit our category page.

Source: original article.